Heat and Mass transfer in Cryogenic Condensers

F. Herzog1, T. Kutz 2,

1Messer Group GmbH, 47803 Krefeld, Germany 2Messer Industriegase GmbH, 65812 Bad Soden, Germany

Friedhelm.herzog@messergroup.com

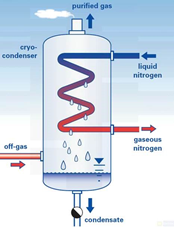

Volatile substances such as solvents, gasoline vapors, or even chlorofluorocarbons (CFCs) can be almost completely condensed in exhaust air streams and process gases by cooling with liquid nitrogen and thus separated from the gas stream. Depending on the requirement, the gas flows are brought to a temperature of down to -170 ° C in the cryocondensers used for this purpose.

When the cryocondensers are cooled directly with liquid nitrogen, the apparatuses cool down to such an extent that the vapors to be separated mostly freeze out and quickly block the gas path. Therefore, defrosting of the condensers is usually required after a few hours of operation. In addition, aerosols, finest mist droplets, are formed which are hardly retained in the cryocondensers and therefore greatly affect the separation efficiency of the apparatus. This means that the actual process gas loading is significantly higher than one would expect based on vapor pressure calculations.

Ice formation can not be avoided if the tube wall temperature inside the condenser is below the freezing point of the exhaust air constituents. But you can reduce the temperature difference between the process gas and the cooling medium and thus reduce ice and aerosol formation. This is achieved when no liquid but cold gaseous nitrogen is used for cooling. Heat and mass transfer can be controlled so much better and the disturbing influence of ice layers is considerably smaller. The substances to be condensed are mainly liquefied and barely frozen. In this way, the residual vapor concentration of the gas streams can be depleted down to the lower mg/m³ range.

When cooled with cold gas, the evaporation enthalpy of liquid nitrogen, the largest part of the cold energy, is not available in the condenser. However, in order to avoid unnecessarily high liquid nitrogen consumptions when operating cryogenic condensers, Messer has developed the DuoCondex® process. This method allows the cooling of cryocondensers with gaseous nitrogen with full utilization of the vaporization enthalpy and the sensitive cold of the cooling medium, without facing the disadvantages of directly with liquid nitrogen cooled cryocondensers.