Water losses during freezing: key influencing factors

V. Mulot 1, 2, 3, D. Pathier 1, H. Benkhelifa 2, 3, FT. Ndoye 2, D. Flick 2, 3

1Air Liquide Paris Innovation Campus 1 chemin de la porte des Loges Les Loges en Josas F-78350, France

2IRSTEA, Genie des Procédés Frigorifiques (GPAN) Antony, F-92160, France

3AgroParisTech, Inra, Université Paris-Saclay, UMR Ingenierie, Procedes, Aliments (GENIAL) Massy, F-91300, France

Didier.pathier@airliquide.com

In food industry, the freezing process in an old and well-controlled process in terms of heat transfer while we are still working to better understand this process in terms of mass transfer (dehydration). In food industry, this dehydration causes 1 to 6% of losses when out of control. The target of this study is to produce reliable and reproducible data and then use these data to better understand dehydration during different style of freezing process. This could help to optimize the food freezing processes and generate significant profits by reducing the product losses and improving its quality.

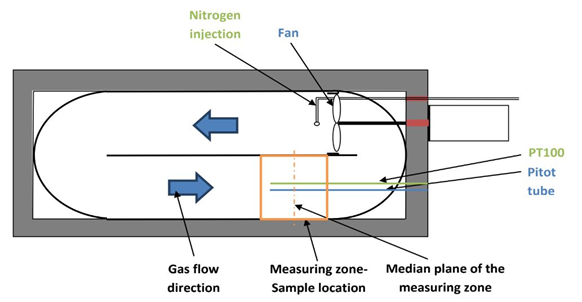

To achieve this target, we built a freezing cabinet that offers stable and reproducible freezing conditions (temperature and heat transfer) all over the freezing volume. The cabinet was equipped with a dedicated scale that can measure the weight of a product being frozen.

For testing this system, some standard blocks of Tylose® (Methylcellulose gel) were frozen. The results show that this cabinet offers stable and reproducible freezing conditions all over the freezing volume and a good repeatability in terms of weigh losses measurements.

Based on this reliable tool, we conducted different tests that show the impact of the following factors on the dehydration during freezing:

- freezing temperature (temperature of the cooling gas in the freezer): We tested three different temperatures: -30°C as a simulation of a standard mechanical freezer, -50°C as a simulation of a very cold mechanical freezer and -100°C as a simulation of a cryogenic freezer,

- velocity of the cooling gas in the freezer: We tested three different speed: 3m/s and 3.9m/s as a simulation of a freezer with a standard ventilation and 7.7 m/s as a simulation of a high speed ventilation freezer,

- product initial temperature: we froze product with an initial temperature of +5°C and +20°C,

- product surface and shape: All the product we froze where flat but some of them offer a smooth surface while other products offer a grooved or a perforated surface.

The results show that the freezing temperature and the initial temperature of the product have a great influence while the gas velocity and the product surface have a limited impact on dehydration during freezing.

Freezing cabinet used in the tests