Proving that haemodialysis can in principle be improved is not enough, in Prof Dimitrios Stamatialis' opinion. "I want to bring innovation to the patient," he says. His new dialysis filters could make a difference. "The knowledge and technology are there. "

In collaboration with the Dutch Kidney Foundation (Nierstichting), Stamatialis is working on innovations for better and compact dialysis systems that can also be used outside the hospital. "My research realises several steps along that path," Stamatialis says. And with success. He developed a new type of dialysis filter in the lab that removes more and better waste products. And that is much needed.

Solution for residual waste

Current haemodialysis not only keeps patients at the dialysis centre three days a week, but also removes only 5-10% of waste products from the blood. The residual waste products are believed to cause the cardiovascular disease, exhaustion and itching that people with kidney failure suffer from. Stamatialis found a solution to that problem.

TOO LARGE waste products

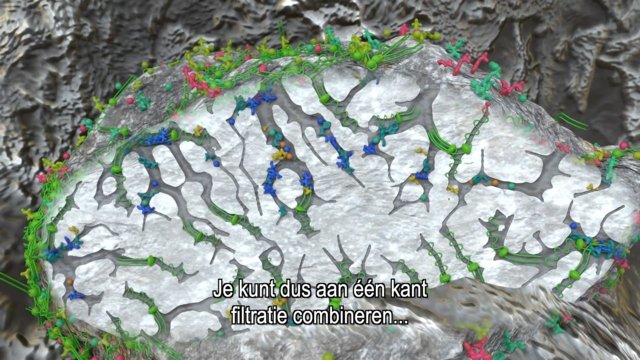

Removing waste products is done with a filter in the haemodialysis machine. This now consists of a finely folded membrane, with very small pores on one side. Blood runs along one side of the membrane and dialysis fluid along the other. The composition of the dialysis fluid attracts waste particles; small particles fit through the pores and thus disappear from the blood. Stamatialis: "But many waste particles are too large because they are bound to proteins. Think of broken-down medicines. So these remain in the blood. Another problem with the current filter is that it gets clogged up with small blood clots during dialysis. This reduces the filtering effect considerably."

Activated carbon filters more

To the filter, Stamatialis first added a layer of activated carbon. Research proved that this way two to three times more and more different large, toxic waste particles are filtered out of the blood. To also solve the clotting problem, Stamatialis turned the filter inside out. "Research into this is still ongoing, but the first results are good: fewer blood clots are formed, which clogs the filter less."

From lab-size to human-size

The result: more and better filtration of waste products. But Stamatialis' innovations are not yet ready for use in dialysis devices. A dialysis filter consists of 30,000 filter units. Stamatialis' filter is a small version with 30 units and has been tested with bags of blood. "We now want to scale up this concept to a format usable for humans. For that, we need to design a reliable and affordable production process. And then prove that it works safely for people and reduces side effects such as cardiovascular disease."

An additional idea that will be investigated is to add a certain substance to the activated carbon that traps bacteria particles away from tap water. Stamatialis: "Then you would no longer need hundreds of litres of sterilised dialysis fluid, just bags of dialysis ingredients that you dissolve in tap water. This brings haemodialysis outside the dialysis centre a big step closer."

Within five years

But so the first step is to make the new filter on a large scale. "That can be done within five years," Stamatialis says. "Another five years later, the filter could then be used in the clinic. "As a scientist, I can prove that haemodialysis can be better - and leave it at that. But I consciously choose projects that bring innovations all the way to the patient. I still have a good ten years to go before retirement. And I am determined: before then, I want to make better haemodialysis possible."

More information

This research is conducted in collaboration with the Dutch Kidney Foundation (Nierstichting). Within the University of Twente, this research falls under the TechMed strategic impulse programme KETs4PM on 'Personalised Renal Health', of which Prof Dr Dimitrios Stamatialis is the coordinator. Stamatialis is professor of (Bio)artificial organs in the Advanced Organ Bioengineering and Therapeutics (AOT) department.