Thomas Leigh Hackett, a PhD student at the Integrated Devices and Systems department, has come up with a way to improve a flow sensor's air speed measurements by 511%. The sensor also extracts information on the direction and moisture of the air. Unlike traditional flow sensors, designed to measure only one parameter in isolation, Thomas’s method captures a range of data using a single MEMS chip (microelectromechanical systems). This sensor could help with optimising conditions in vertical farms and managing airflow in data centres where understanding the whole environment is key.

‘With just one flow sensor, we can extract far more information. That means we can use less expensive hardware and invest more in advanced analysis. Our sensor, as a research prototype, isn't perfect in the conventional sense — it's more sensitive to those external factors. Instead of only capturing flow data, it also picks up temperature, humidity, and other environmental clues. Unlike the wider sensors community, we see this as an opportunity, not a hindrance. It enables us to extract more information using one sensor’, Thomas explains.

All on one chip

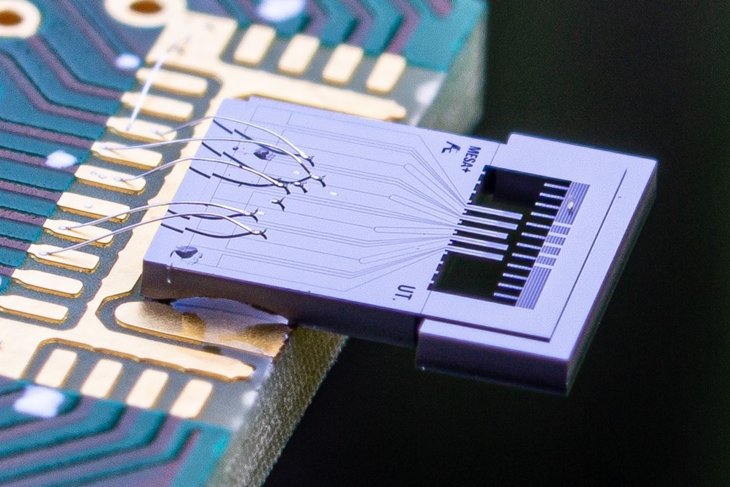

Aside from reimagining sensing techniques, Thomas also tries to improve how flow sensors are made. Most flow sensors are fabricated through bulk micro-machining — an elaborate and chemical-heavy process. With a CMOS-based design, however, both the sensor and the data processing are made on the same silicon chip.

“Now the brain power is on the sensor itself,” Thomas says. With traditional sensors, two separate chips are needed: one for capturing the signal and one for interpreting it, and the two are connected with tiny wires, adding extra steps and costs to the process. But with CMOS, the sensor and the computer chip are on the same piece of silicon. So, the sensor (on the top layers of the chip) captures the data, and the computer (on the lower layers) interprets it—all on a single chip. “This way we’re also cutting production costs in half because we don't need the MEMS foundry: everything is done in the same facility,” he says.

Smart sensors for smart horticulture

This leap in sensor capability has wide-reaching potential. For example, in greenhouses and vertical farms — indoor farms where plants are grown in stacked layers — airflow is essential for plant health. It reduces mould, disease, and other risks caused by stagnant, humid air.

“Our sensors can detect air movements as light as 0 to 1 metres per second. By placing these sensors around plants, farmers can monitor airflow with amazing accuracy.” They can also track temperature and humidity to create optimal growing conditions conducive to higher crop yields.

Data centre cooling

Data centres, which house rows of servers running 24/7, could also benefit from these sensors. To prevent overheating, data centres use air cooling or liquid cooling, with air cooling being the more common and cheaper option. Air cooling relies on fans that blow cool air over the servers to carry the heat away. But in these big spaces, airflow isn’t always smooth. Some areas don’t get enough air movement, creating what are called dead zones where stagnant air might cause heat buildup. This can slow down the servers, causing hardware damage, and, in extreme cases, even fires.

“We’re working to make our sensors measure airflow in real time. By placing these sensors throughout a data centre, you’ll be able to detect dead zones, so you can adjust fans or cooling setups to circulate the air more evenly,” he says.

IEEE Sensors Conference

Thomas recently presented his research at the IEEE Conference in Japan. “I was listening to one of the speakers talking about how Twente is a world leader in flow sensors and MEMS technology. It was surreal hearing our work cited again and again.”

Reflecting on his research, he adds, “It’s exciting to be doing my PhD at a place that’s really a world leader in this area.” He hopes to continue his research in CMOS & MEMS integration, scale manufacturing, and other possible applications for this type of flow sensor across industries.