Manufacturing Microfluidics with 3D printing

Thursday, 5th of October, 09:00–09:30

Drs. ing. Jan Eite Bullema, Senior Scientist at TNO Technical Sciences

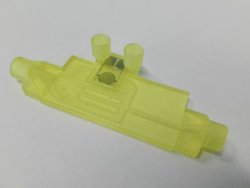

3D Printing / Additive Manufacturing appears to be an attractive technology to realize fluidic devices. By many still mainly seen as technology for development purposes, as 3D printing makes it relative easy to make small series with design iterations (e.g. different inlet apertures, different channel length, mixer size). In fact 3D printing evolves rapidly as a manufacturing technology. This is especially true for fluidic devices that have a more complex design – like many organ-on-chip devices. Recent developments in 3D printing have made 3D printing more attractive as a manufacturing technology. Dolomite has introduced the Fluidic Factory 3D printer for fast prototyping. The Continuous Liquid Interface Process (CLIP) announced by Carbon in the beginning of 2015, makes VAT polymerization 100 timed faster. Carbon has demonstrated (and patented) production of microfluidic products. At TNO we have developed production equipment that enable low cost production of integrated microfluidics with 3D printing.

3D Printing / Additive Manufacturing appears to be an attractive technology to realize fluidic devices. By many still mainly seen as technology for development purposes, as 3D printing makes it relative easy to make small series with design iterations (e.g. different inlet apertures, different channel length, mixer size). In fact 3D printing evolves rapidly as a manufacturing technology. This is especially true for fluidic devices that have a more complex design – like many organ-on-chip devices. Recent developments in 3D printing have made 3D printing more attractive as a manufacturing technology. Dolomite has introduced the Fluidic Factory 3D printer for fast prototyping. The Continuous Liquid Interface Process (CLIP) announced by Carbon in the beginning of 2015, makes VAT polymerization 100 timed faster. Carbon has demonstrated (and patented) production of microfluidic products. At TNO we have developed production equipment that enable low cost production of integrated microfluidics with 3D printing.

With 3D printing technology it becomes possible to manufacture functional 3D fluidic structures, e.g. serpentine mixers, Brownian ratchets, Tesla valves. 3D printing makes it also possible to easily integrate fluidic functionalities, like mixing, valving, metering in one device. Which leads to a reduction of integral device costs. It is expected that especially for complex integrated lab-on-a-chip / organ-on-a-chip devices, 3D printing will become the production technology of choice.

With 3D printing technology it becomes possible to manufacture functional 3D fluidic structures, e.g. serpentine mixers, Brownian ratchets, Tesla valves. 3D printing makes it also possible to easily integrate fluidic functionalities, like mixing, valving, metering in one device. Which leads to a reduction of integral device costs. It is expected that especially for complex integrated lab-on-a-chip / organ-on-a-chip devices, 3D printing will become the production technology of choice.

Engineering microfluidic organ-on-a-chip systems

Thursday, 5th of October, 15:30–16:00

Prof. dr. Sabeth Verpoorte, Professor of Pharmaceutical Analysis, Research Institute of Pharmacy, University of Groningen, The Netherlands

Engineering cellular microenvironments that more accurately reflect the in vivo situation is now recognized as being crucial for the improvement of the in vitro viability and in vivo-like function of cells or tissues. Microfluidic technologies have been increasingly applied since the late 1990’s for this purpose, with a growing number of examples of perfused cell and tissue cultures in microfluidic chambers and channels. The well-defined solution flows provided by microfluidics mean enhanced cell growth and function through improved nutrient delivery and waste removal. Additional benefits include the implementation of well-defined temporal and spatial (bio)chemical gradients, and mechanical signals that cells experience in their natural environment. Because the ability to culture cells and tissue under such controlled conditions leads to cellular function that is distinctly more organ-like, the microfluidic systems used are now referred to as “organs-on-a-chip” or “microphysiological systems”. Reported organ-on-a-chip systems are as diverse as the biological models they have been designed to study. Most examples are based on cell culture models, which involve seeding cells into a chip with the eventual formation of a 2D or 3D tissue-like structure. The biological approach in these cases could be regarded as “bottom-up”. Less common are the “top-down” biological approaches, in which organotypic tissue samples are directly obtained from mammals or human subjects for further study. Regardless of the biological model of interest, all organ-on-a-chip systems must be designed to accommodate cell or tissue culture, which implies precise peripheral control of medium transport to and from the chip. The use of microfluidics to do this rather than a pipetting instrument of some kind opens up the possibility for continuous perfusion of cell or tissue culture, a starting point for the creation of cellular microenvironments that are more representative of the in vivo situation. Moreover, peripheral pumping systems can be configured to change the composition of perfusion media at specifically programmed timepoints throughout the experiment to include compounds expected to induce some form of cellular response. This enables the definition of time-varying dosing experiments of drugs, nutrients or other compounds that reveal real-time effects on cells, something which is far more tedious or even impossible to accomplish in more conventional well plate formats.

Engineering cellular microenvironments that more accurately reflect the in vivo situation is now recognized as being crucial for the improvement of the in vitro viability and in vivo-like function of cells or tissues. Microfluidic technologies have been increasingly applied since the late 1990’s for this purpose, with a growing number of examples of perfused cell and tissue cultures in microfluidic chambers and channels. The well-defined solution flows provided by microfluidics mean enhanced cell growth and function through improved nutrient delivery and waste removal. Additional benefits include the implementation of well-defined temporal and spatial (bio)chemical gradients, and mechanical signals that cells experience in their natural environment. Because the ability to culture cells and tissue under such controlled conditions leads to cellular function that is distinctly more organ-like, the microfluidic systems used are now referred to as “organs-on-a-chip” or “microphysiological systems”. Reported organ-on-a-chip systems are as diverse as the biological models they have been designed to study. Most examples are based on cell culture models, which involve seeding cells into a chip with the eventual formation of a 2D or 3D tissue-like structure. The biological approach in these cases could be regarded as “bottom-up”. Less common are the “top-down” biological approaches, in which organotypic tissue samples are directly obtained from mammals or human subjects for further study. Regardless of the biological model of interest, all organ-on-a-chip systems must be designed to accommodate cell or tissue culture, which implies precise peripheral control of medium transport to and from the chip. The use of microfluidics to do this rather than a pipetting instrument of some kind opens up the possibility for continuous perfusion of cell or tissue culture, a starting point for the creation of cellular microenvironments that are more representative of the in vivo situation. Moreover, peripheral pumping systems can be configured to change the composition of perfusion media at specifically programmed timepoints throughout the experiment to include compounds expected to induce some form of cellular response. This enables the definition of time-varying dosing experiments of drugs, nutrients or other compounds that reveal real-time effects on cells, something which is far more tedious or even impossible to accomplish in more conventional well plate formats.

This presentation will focus on examples from our labs in which we have designed "top-down" and "bottom-up" organ-chips incorporating means to both monitor culture conditions and quantify cell behaviour. Our “bottom-up” example constitutes the culture and investigation of primary human endothelial cells in microfluidic devices. In a simple demonstration of the importance of microenvironment in cell culture, clear differences in cell phenotype are observed when human umbilical vein endothelial cells grown in microchannels and well plates are compared. In a “top-down” example, a microfluidic device was designed for perfusion culture of precision-cut organ slices. Metabolic studies employing precision-cut liver slices and on-line HPLC analysis were successfully demonstrated with this device, as was a multi-organ slice experiment showing regulation of bile acid synthesis in the liver by the intestine.

Porous Media everywhere! Microfluidic experience and opportunities in Shell

Friday, 6th of October, 09:00–09:30

Prof. ir. Cor van Kruijsdijk, Sr. Principal Researcher at R&D Physics, Emerging Technologies, Shell IR&D, The Netherlands

The use of microfluidic devices in Shell goes back to the 1980’s where we studied the dynamic behaviour of a brine, H2S, sulphur mixture  at subsurface conditions, T=120 [C], p=31 MPa. Here safety was the biggest driver for the choice of microfluidics. Currently we have a focus on chemically enhanced oil recovery where we are studying the fundamental processes of oil displacement by chemically enhanced water. Microfluidic devices are also starting to penetrate other divisions in Shell. Many processes in “New Energies” take place in porous media of one kind or another, batteries, photo-chemical/electrical cells, porous catalytic bed reactors etc. Moreover, microfluidic devices are finding its way in analytical chemistry either for sample preparation and/or direct measurement of fluid properties and composition. A significant part of these processes can be studied using currently available technology. However, some of the catalyst supported gas reactions push past the current operating envelopes of microfluidic devices as they require temperatures upwards of 1000 [C]. Moreover, the currently available spectroscopic methods for in-situ measurements are challenged by the small densities of the gas phase.

at subsurface conditions, T=120 [C], p=31 MPa. Here safety was the biggest driver for the choice of microfluidics. Currently we have a focus on chemically enhanced oil recovery where we are studying the fundamental processes of oil displacement by chemically enhanced water. Microfluidic devices are also starting to penetrate other divisions in Shell. Many processes in “New Energies” take place in porous media of one kind or another, batteries, photo-chemical/electrical cells, porous catalytic bed reactors etc. Moreover, microfluidic devices are finding its way in analytical chemistry either for sample preparation and/or direct measurement of fluid properties and composition. A significant part of these processes can be studied using currently available technology. However, some of the catalyst supported gas reactions push past the current operating envelopes of microfluidic devices as they require temperatures upwards of 1000 [C]. Moreover, the currently available spectroscopic methods for in-situ measurements are challenged by the small densities of the gas phase.