Research topic: Biomass (catalysis)

Research group: Faculty of Science & Technology/Catalytic Processes & Materials

People involved: Prof. dr. K. Seshan

Contact: k.seshan@utwente.nl (361, Meander, 053-489 3254)

Catalysis is central to the current fossil feedstock based economy. About 70% of all industrial processes make use of catalysts, while approximately 90% of produced chemicals are prepared with the aid of catalysts. The universal principle of catalysis - defined by Berzelius as the phenomena that changes the rate of a reaction without the catalyst being altered - can be found in many different disciplines within the field of chemistry. A few examples in daily life are: exhaust catalysis, batteries, detergents, gasoline, food (beer, wine, and cheese), polymers, medicines etc. However, the increasing cost of fossil feedstock’s, diminishing reserves, concerns related to their environmental impact and greenhouse gas effect mandate transition to a renewable bio-based economy. Catalysis for sustainability is one of the central themes of the research group. Catalysis is multidisciplinary and connects many issues: from inorganic chemistry for catalyst preparation, to surface science, physical chemistry and reactor- and process- design. In other words, catalysis provides challenges for scientists with a broad interest.

1.Fuels by biomass liquefaction

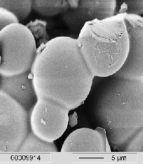

Pyrolysis of biomass is a simple and efficient way to liquefy solid biomass. Bio-liquids have distinct advantages over solid biomass: i) bioliquids are easier to store, to transport and to process, ii) bio-liquids have a much higher volumetric energy density and iii) contain typically much less contaminants (S, Cl, N, alkali metals) than the biomass feedstock. Fast pyrolysis of biomass allows liquefaction of all the major constituents, i.e., cellulose, hemicellulose and lignin, and the result is a bio oil with a similar elemental composition as the biomass feedstock. Pyrolysis is attracting a lot of attention at the moment and the product is seen as a promising second generation energy carrier and biofuel. However, the bio oil produced by fast pyrolysis is i) acidic/corrosive ii) unstable due to condensation reactions iii) has a lower energy density than fossil oil and thus requires extensive post-treatment before it can be used as a transportation fuel [2]. The aim of this study is to develop a novel catalyst and process method in laboratory and pilot plant scale to improve the quality of bio-oil.

2.Fuels by biomass gasification

Conversion of carbon based feed stocks, e.g, coal, methane, and higher hydrocarbons to syngas (CO+H2 mixtures) via steam reforming and subsequent conversion to fuels is of tremendous interest. Presence of catalysts is mandatory for efficient reforming, nickel based catalysts being the most commonly used in commercial applications. Role of water as one of the reactants make the reaction strongly endothermic and the process energy intensive. Catalyst design to enhance water activation is thus of crucial importance to enhance efficiency of the reforming reaction. Carbon present in the feed adds severe coking and catalyst deactivation as additional issues for application. Catalyst design principles are reasonably well established for methane reforming, and commercial operation is routinely practiced. However, while considering sustainable feed stocks such as biomass, coke and tar formation is much more severe and requires a new look at catalyst design. Application of steam reforming for fossil to sustainable feed stocks including waste carbonaceous materials is the central theme of research and carried out from the point of view of efficient catalyst design.