Ph.D. thesis

Thesis title: | Wear and friction of nanostructured zirconia and alumina ceramics and composites |

Year: | 1999 |

Promotor: | Prof. Dr. Ir. H. Verweij |

Assistant promotor: | Dr. A.J.A. Winnubst |

Summary

The work described in this thesis is about wear and friction of zirconia and alumina ceramics and composites of zirconia and alumina. Tribological properties are system properties that can only be studied for given combinations of materials and operating conditions. The tribological properties of ceramics, however, are particularly influenced by the homogeneity of the ceramic microstructure. Important parameters of that are porosity, grain size and possibly phase dispersion homogeneity of composites. In this thesis mainly attention was paid to the preparation of ceramic systems, as homogeneous as possible and the influence of homogeneity on tribological properties. The preparation of homogeneously structured composite material was mostly done by conventional processing but occasionally extreme homogeneity was achieved by colloidal processing.

The preparation of dense homogeneous zirconia-toughened alumina (ZTA) with high dry sliding wear resistance is described in chapter 2. These ZTA ceramics were sintered for 2 hours at 1400°C and consists of a homogeneous distribution of zirconia grains in an alumina matrix with grain sizes of 0.2 and 0.5 (m, respectively. Tribological measurements revealed for these materials a very low specific wear rate (app. 10-9 mm3/Nm) and a coefficient of friction of 0.5 with alumina as the counter material. It is shown that, in this case, wear is dominated by abrasion and polishing.

Zirconia toughened alumina (ZTA) composite, prepared by colloidal filtration.

The influence of the second phase of alumina or zirconia on the tribological properties of zirconia and alumina, respectively, is dealt with in chapter 3. It was shown that, with initial Hertzian contact pressures up to 1 GPa and sliding velocities up to 0.5 m/s, the specific wear rate was the highest for Y-TZP, 10-6 mm3/(N·m), and the lowest for ZTA, 10-9 mm3/(N·m). For both single-phase zirconia and alumina ceramics it was found that addition of a harder (alumina) or a tougher (zirconia) phase, respectively, leads to an improved wear resistance. Depending on the test conditions the wear mechanisms are abrasion, delamination and polishing. The main conclusion of this work is that ZTA composites manufactured and tested in this study have a superior wear resistance and a relatively low coefficient of friction under dry sliding conditions.

The results of measurements on some exceptionally wear-resistant materials are given in chapter 4. ZTA ceramics, prepared by colloidal processing, show an improvement in wear resistance of >3 orders of magnitude in dry-sliding self-mating tests compared to less homogeneous ZTA, prepared by conventional processing of commercial powders. The composite ceramics also show superior tribological behaviour compared to self-mating (-alumina and yttria-stabilised zirconia couples.

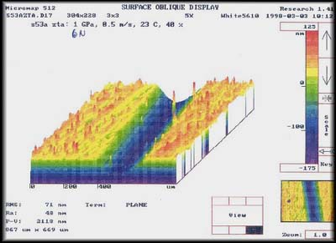

Surface of worn ZTA sample

Modelling of the tribological results is described in chapter 5. The objective of this study is to introduce a wear map of ceramics which shows the different regimes of dominant wear modes observed for a wide range of material properties and operational conditions. For this purpose, friction and wear tests are carried out with tetragonal zirconia discs sliding against various pin materials under various contact pressures and sliding velocities. The sliding wear phenomena observed in all tests can be classified into two types: "mild wear" and "severe wear". If the specific wear rate exceeds the value of 3(10-6 mm3/(N(m), wear is indicated as "severe". The critical condition for transition from mild to severe wear is obtained with an intergranular fracture model that considers both mechanical and thermal properties. A wear map of ceramics, in which the mild and severe wear regimes can be distinguished, is introduced using two dimensionless parameters, namely an existing mechanical severity of contact (MS) and a newly developed thermal severity of contact (TS). The availability of the wear map constructed by this method is proven by the experimental results observed for a wide range of test material properties and operational conditions.

Chapter 6 describes the preparation and frictional properties of alumina and Y-TZP ceramic composites with small amounts of soft oxide additives. The concentration of additive was kept low to preserve the mechanical properties of the matrix ceramics. Various single oxide additives (ZnO, MgO, CuO, B2O3 and MnO2) were used to establish which oxides could result in a significant friction reduction in dry sliding pin-on-disc experiments against alumina or Y-TZP balls. All additives resulted in medium friction (app. 0.5) for dry sliding of ceramics with alumina and high friction (> 0.65) for ceramics with Y-TZP. The addition of CuO in alumina or Y-TZP reduced the coefficient of friction from 0.65 to 0.45.

In chapter 7, the relation is described between ceramic wear in practice and laboratory test results. The practical case study focuses on mechanical seals in a cogwheel pump. Besides tribological issues, manufacturing and engineering issues are addressed as well. The results show that a good prediction can be made of the performance of ceramic materials classes under practical conditions on basis of tribological laboratory tests. In addition it was found that practical operational conditions showed significant variation. This led to the conclusion that a materials selection narrowed down by practice test must again be followed by accurate and reproducible laboratory test again.

In chapter 8 an evaluation of the presented work is given together with recommendations for future research, development and production. First, it is necessary to look for more applications in which the advantageous properties of ceramic materials fully justify their use. Second, the reduction of friction is should receive more attention because the use of ceramic materials in tribosystems may be further promoted when friction is low. Finally, it may be important to obtain the bulk materials with favourable tribological properties in the form of well-defined coatings on "cheap" substrates. This will significantly reduce cost-price and hence open perspectives for a wide range of applications including consumer products.