Project Members

Jaap Flokstra (Project Leader)

Bob Rots (Bachelor student)

Michael Garcia (Bachelor student)

Wilco Vessies (Bachelor Student)

Former Members

Wolter Hoving (Master student)

Wiemer van der Veur (Bachelor student)

Cor Molenaar (Bachelor student)

Introduction

The multi sensors multi satellites project is part of the MISAT cluster of the Dutch MicroNED program. In this project sensors are developed which are suitable for space applications in microsatellites. Because of the size of the satellite there are strong demands on the size, weight and power consumption of the sensors.

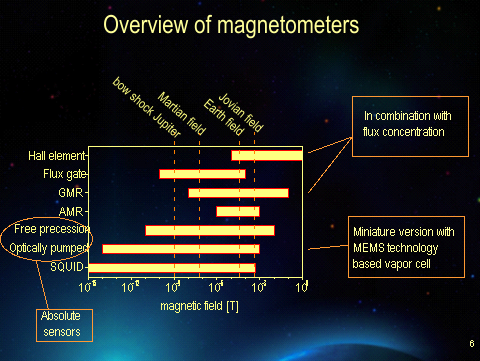

In a large number of space missions a wide variety of sensors has been applied. In this project the focus is on distance, gravity and magnetic field sensing. At this point in the project the main focus has been on magnetic field sensing. There is a wide variety of magnetic field sensors available, the most important ones are displayed in the figure below. We consider two approaches: The first approach is a Hall element or GMR in combination with flux concentration techniques. The second approach is a miniature version of a optically pumped magnetometer.

Hybrid Magnetometer Based on a High Tc Flux Concentrator

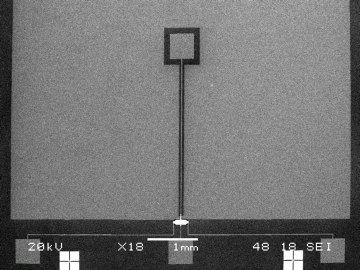

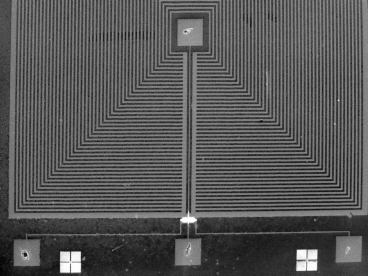

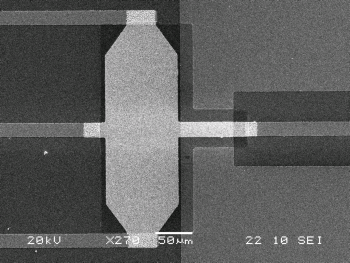

This magnetometer contains a high Tc superconducting ring which is tightly coupled to a normal conducting sensor. Several magnetometer designs have been produced. In the SEM pictures below some examples are displayed. The concentrator is made of pulsed laser deposited YBCO. The sensor is a Hall element made of Bismuth which has been deposited by rf-sputtering.

In the picture above an SEM image is displayed of the large part of the sensor. In the bottom part of the image the sensor and the electrical connections are displayed.

Besides the solid concentrators we also fabricated designs where the concentrator is divided in narrow strips as displayed in the figure above. The main reason for this is to prevent vortex trapping in the superconducting concentrator.

In the SEM image above a close up is displayed of the Bi sensor directly next to the constriction.

As mentioned, the body of some concentrators is divided into narrow strips. The movement of trapped flux vortices gives rise to 1/f noise. By dividing the body into narrow strips this vortex trapping can be prevented improving the low frequency sensitivity of the sensor.

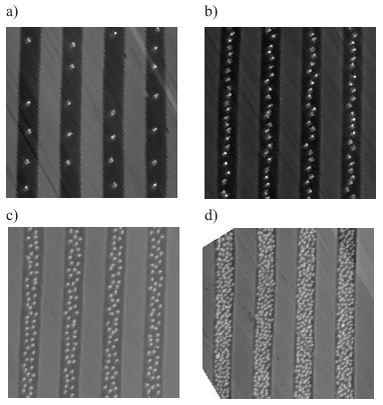

Vortex trapping and expulsion in superconducting strips extensively investigated. By means of a scanning SQUID microscope which can measure the spatial distribution of the magnetic field, vortices can be visualized like displayed in the figure below.

These images show the spatial distribution of magnetic field 35 µm wide strips which are cooled down in respectively 5 (a), 10 (b), 20 (c) and 50 (d) µT. The vortices are the bright dots in the strips. So when the field during cool down increases more and more vortices are visible in the strips.

Miniaturized Optically Pumped Magnetometer

In optically pumped magnetometers modulated monochromatic light, for example from a laser, is passed through a gas cell which contains an alkali metal vapor. At a certain modulation frequency (Larmor frequency) of the laser, the light can for example be absorbed or the polarization can be rotated. The Larmor frequency of the alkali material is given by a material dependent gyromagnetic ratio multiplied by the applied field.

The biggest advantage of such a magnetometer is its capability to perform an absolute field measurement. A variety of optically pumped magnetometers has been applied in space missions but all the applied magnetometers contained large glass gas cells. We are considering the possibilities of MEMS technique based cells which are made of a stack of wafers.

Refereed Publications:

Vortex trapping and expulsion in thin film YBa2Cu3O7-δ strips

K. H. Kuit, J. R. Kirtley, W. van der Veur, C. G. Molenaar, F. J. G. Roesthuis, A. G. P. Troeman, J. R. Clem, H. Hilgenkamp, H. Rogalla, and J. Flokstra

Phys. Rev. B, 77, 134504, (2008)