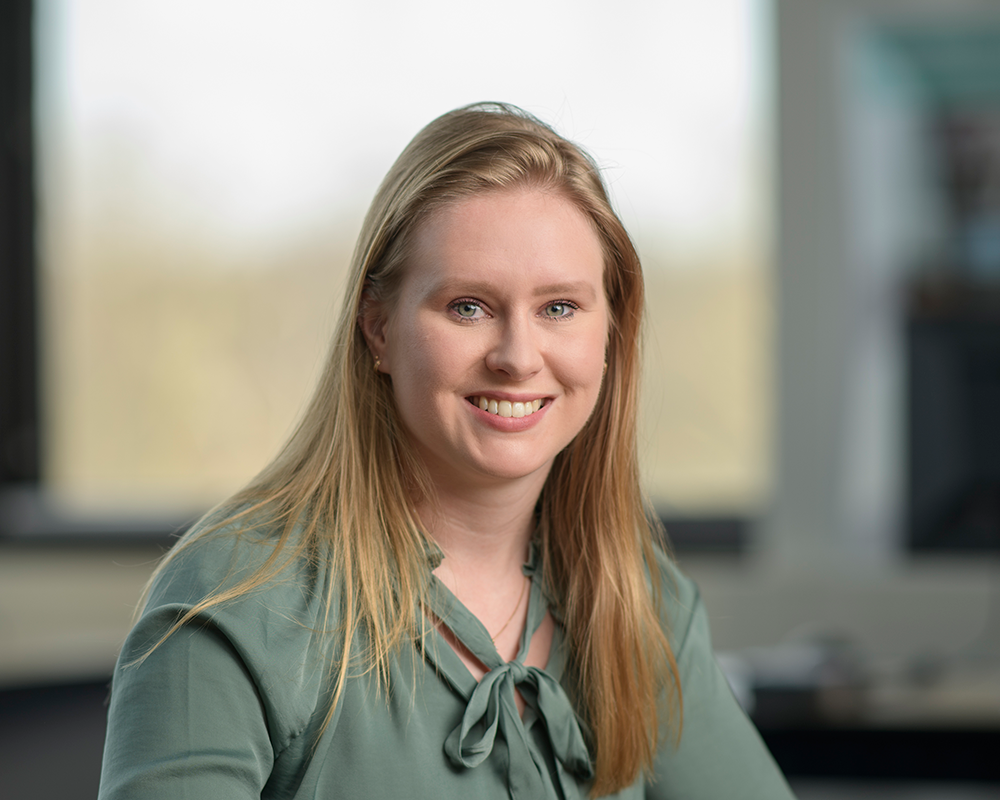

Work with the

best minds

Our team consists of the brightest minds across Europe and experts in areas like Digital Twinning, Computer-Aided Engineering & Manufacturing, Additive Manufacturing, Manufacturing Systems, Artificial Intelligence, and more. We can help your team solve tough manufacturing problems, learn the skills they need to thrive in a digital environment, and design exceptional products that serve the global community. We also offer training online and onsite to help professionals stay ahead of the curve and learn how to use cutting-edge technology and techniques.

Fraunhofer Innovation Platform for Advanced Manufacturing at the University of Twente (FIP-AM@UT) works with manufacturing organisations like yours to produce breakthrough industry research and test new ideas on our state-of-the-art shopfloor. Experiment with new theories, conduct research, and iterate with our AI-supported advanced manufacturing tools, demonstrators, and testbeds. We’ll help your business create a project implementation roadmap that uses the latest integrated manufacturing solutions.

When you work with FIP-AM@UT, your team gains access to a multifaceted, collaborative network of innovators, researchers, and inventors. Collaborative relationships and personalised support are at the heart of everything we do here. We can help you find the best collaborators to move your project forward and create inventive solutions to tough problems.

We’re committed to stimulating growth and development within the global manufacturing industry through technological enablement, applied research, and project support. At FIP-AM@UT, we want the best manufacturing minds to have access to everything they need to drive innovation. Join us as part of a project consortium or engage with directly, and start creating the future of advanced manufacturing solutions.

Ready to tackle your next big project? Collaborate with us and get support from the best and brightest in the industry.