Objectives:

Currently, expensive and time-consuming outdoor tests are the best and most reliable methods to evaluate new materials for tires. Developing laboratory test methods which allow predicting the outdoor behavior of a tire is one of the leading goals in this project.

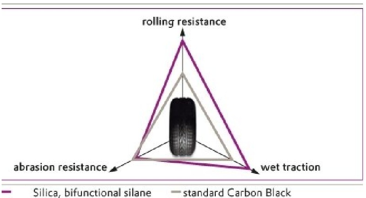

The replacement of carbon black, for more than 100 years the preferred filler in tires, by a silica/coupling agent system shifted tire performance to a higher level, especially in terms of rolling resistance and wet grip while maintaining abrasion resistance, as illustrated in the magic triangle. This technology is nowadays implemented by all tire producers; the first one was the so-called ‘Green tire”, which lead to a fuel reduction of 5%. Which means significant reduction if global fuel consumption is considered.

The crucial factor for the property improvements is a good filler-polymer interaction. The introduction of silica/silane systems is just a first step in this direction; there is still a major potential for even better and more tailored polymer-coupling agent-filler systems. The development of new materials for tires based on innovative filler systems as well as functionalized polymers is the second goal within this project.

Driving force of the project:

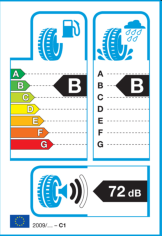

All tires produced after 1 July 2012 must have a label indicating energetic efficiency, safety and noise. The aim of this information is to ensure that consumers can make more considerate decisions, helping to save energy and CO2 – emissions of their cars.

Challenges:

- Prior work in tire development was focused on rolling resistance, as this determines the fuel consumption of the tire. Lately, the focus shifted to safety, for which wet skid is the most important tire property. The knowledge about the correlation between material composition, properties and wet skid resistance is limited.

Open questions which this project addresses are:

- What are the circumstances, under which dynamic properties have to be measured in order to get a reliable prediction of wet skid?

- To which degree does the wet skid performance of a tire tread depend from its dynamic properties?

- What is the contribution of the material characteristics such as rubber type, filler structure, rubber – filler interface and crosslink network to wet skid and rolling resistance?

- What is the correlation between laboratory measurements which are relatively simple and inexpensive and outdoor tests for wet skid resistance?

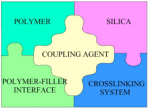

The innovative tire tread material is a composite, whose properties are determined by five major components:

- The polymer

- The filler: silica

- The coupling agent

- The polymer-filler interface

- The crosslinking system

For more information regarding this project, contact S. Maghami and/or E. Cichomski

![]()

![]()