project information

Full title: | Ultra Fast Pyrolysis of Used Car Tyres |

Acronym | UFP-Tyres |

Funding/Programme | M2i |

Duration | 2017-2021 |

Partners | - |

project description

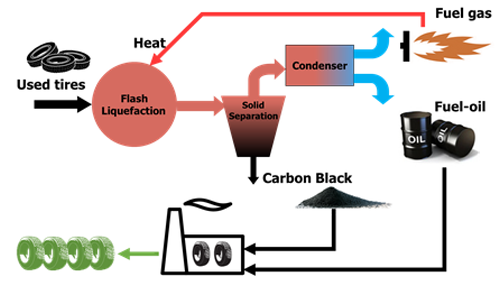

Each year, 800,000,000 tires are discarded, containing approximately 3,500,000 tons of valuable fillers, mainly carbon black. Within the EU, currently more than half of this material is still incinerated. In view of the diminishing resources and resource efficiency, environmental issues and the enormous quantity of waste tires, cradle‐to‐cradle loops have to be elaborated for sound processing of this waste stream. In order to open new markets in high demanding applications including tires, new technologies have to be developed for the recovery of a higher quality carbon black. Besides, other rubber additives like zinc, threatened by scarcity, as well as energy have to be reused. Additionally, the envisaged process is more climate-neutral than production of new materials.

In this project, a new innovative process for waste tire recycling will be developed. The process will convert used tires by a new thermochemical ultra fast pyrolysis process, and will produce a high quality nano-structured carbon black and valuable fuels: both can be used as raw materials for an energy-efficient production of new sustainable tires. The latter also requires tailoring of processing and compounding with the recycled carbon black to achieve material properties comparable to those of virgin material. An initial study showed the feasibility and potential for a breakthrough in quality compared to conventional pyrolysis carbon black, using an innovative technology which is significantly more cost-effective than the conventional pyrolysis processes.