PROJECT AIM

Particulate processes are difficult to predict and highly relevant to many fields such as civil, geotechnical and mechanical engineering. Classically the bulk of granular particles are modeled as continua where a material model is essential. Discrete element method provides a bottom-up approach to accurately predicting the constitutive behavior of a material. However, the cost is formidable for large-scale industry applications. In this project, we aim to develop concurrent multi-scale methods by coupling continuum and particle methods either within an overlapping volume or at contact interfaces where the information is mapped between distinctive scales via coarse graining.

PROJECT DESCRIPTION

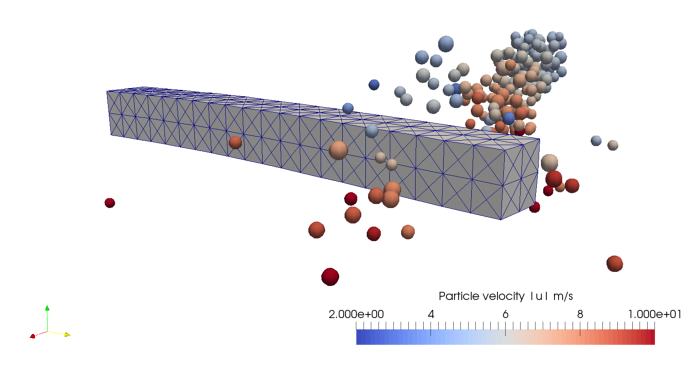

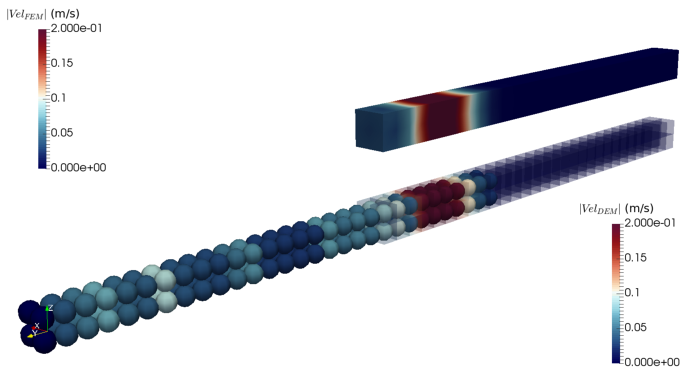

Two FEM-DEM concurrent coupling schemes, namely surface coupling (SC) and volume coupling (VC) have been implemented within a concurrent multi-scale modeling framework. SC is well suited for particle-machinery interaction problems (Fig. 1) where deformation, fatigue, etc. in the structure is important. VC is implemented with the goal to adaptively switch from a discrete particle to a continuum model (Fig. 2), and vice versa, depending on a trade-off between accuracy and efficiency and relevant length/time scales. The method is further developed with the help of coarse graining which allows to map particle scale data to the macro scale while conserving mass and momentum.

Fig.1 Inflow of particles hitting an elastic body

Fig.2 Wave propagation from DEM to FEM