Duration

Start: 01-10-2018

End: 30-09-2022

Partners

Staff

Description

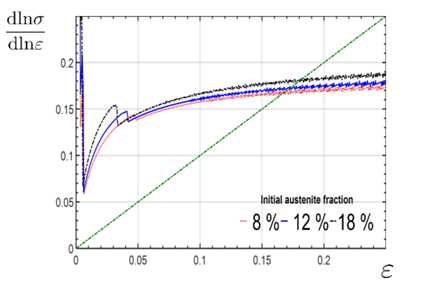

Multi-phase steels, especially Transformation Induced Plasticity (TRIP) steels, combine high strength and high formability, which is a condition for deep drawing parts in the automotive industry. TRIP steel has a microstructure consisting of retained austenite in a ferritic matrix. During straining, the retained austenite phase transforms into martensite and correspondingly the strength increases by the phenomenon of strain hardening. This transformation allows for enhanced strength, ductility and excellent energy absorption capacity. It has been observed at TATA Steel that allowing a small amount of retained austenite phase to be present in Dual Phase steels results in a significant improvement in formability, as shown in Figure 1.

Figure 1: Improved diffuse necking strain due to TRIP effect

This project is an essential part of the Tata DENS program (Digitally Enhanced New Steel product development). In this program a fully linked Through-Process-to-Product modelling chain is developed to enable fast product development and improve on existing products. This should reduce the amount of tests and extend the capabilities of the experimental process route. Last but not least this program aims to create a group of in-house researchers who are expert in over-the-chain thinking. This project focusses on enabling a quantitative prediction of effect of retained austenite on the formability in multi-phase steels. This builds on microstructure features generated earlier in the modelling process chain.