This work is for my master thesis in the Group of Surface Technology and Tribology, Faculty of Engineering Technology, University of Twente.

As a multi-disciplinary project, this project has been inspired by the problems of conventional wound dressings and also comparative studies of biological attachment systems in nature. On the one hand, pain reduction during the removal of an adhesive wound dressing has become an important field of study for clinical practices. The characteristic of an ideal medical dressing is that it adheres safely to the skin around the wound and should easily be detached from the skin without causing any damage during removal. Conventional skin adhesives have exhibited optimum properties in the way that they can hold wound dressings and human skin together securely, but causes tissue damage during its removal, subsequently the exacerbation of the existing wounds. This has led to the priorities for further developments in a way to avoid pain for the patients, which primarily includes the decrease of peel strength between skin and adhesives at the de-boning moment. On the other hand, the remarkable ability of geckos to climb and run rapidly on walls and ceilings has recently received attention from researchers. Their feet are covered by a large number of small setae that contain numerous branches per seta with a lower level of spatulae. This hierarchical structure plays a key role in robust adhesion and easy detachment. Despite massive effort made on the study of gecko-inspired adhesion mechanism, there is still a major concern regarding how to realize this in an easy-removable capacity on human skin in a practical and cost-efficient way. This restricts the wide applications of gecko-inspired adhesives.

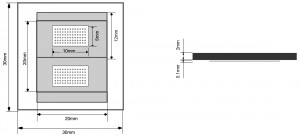

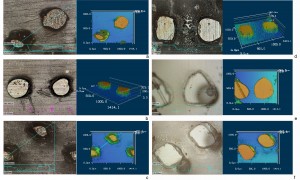

In this work, the theoretical design model was experimentally investigated using fabricated PDMS arrays. Laser cutting was applied as an uncommon fabrication method for gecko-inspired structures. The attachment and detachment properties of various micro-patterned structures with triangular, square and hexagonal patterns, and triangular, square, circular and diamond cross sections were evaluated and compared.

This fabrication technique used here was very successful and practical. Because the thin Teflon molds were pulled directly from the structured material, there was only little damage to the micropillars. In addition, the fabrication of gecko-inspired structure on the micro-moulding of PDMS would appear to offer a near-practical means for manufacture an easy-removal skin adhesives, albeit in its present form with a comparable adhesion strength and a decreased peel strength compared with conventional wound dressings. Therefore, this fabrication method can be further developed to benefit a number of practical applications in skin tissue medical industry.

Acknowledgement:

This work was supported by the Lab of Surface Technology and Tribology in the University of Twente. This work made use of central facilities supported by the Group of Surface Technology and Tribology, Group of Elastomer Technology and Engineering, and Design lab in the University of Twente. The author would like to thank the supervisors Dr. M.B. de Rooij and Prof. E. van der Heide.